Duct cable installation refers to the process of laying and securing cables inside protective ducts or conduits. This method offers several advantages, such as enhanced cable protection, easy cable management, and future scalability. To ensure a successful duct cable installation, here's a step-by-step solution:

Generally, there are six approaches for optical cable installation into a duct, pulling method and air blowing method.

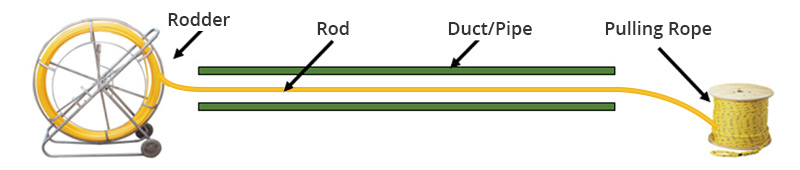

In this method, cables are pulled through the duct manually or using mechanical pulling equipment. Pulling cables require the use of pulling grips or lubricants to reduce friction. It is suitable for shorter distances or when the duct is not obstructed.

Limitations: Optical fiber cables must be handled in compliance with their stated design ratings. Handling crews must be familiar with the cable's design ratings and the critical events during installation where design limits may be approached.

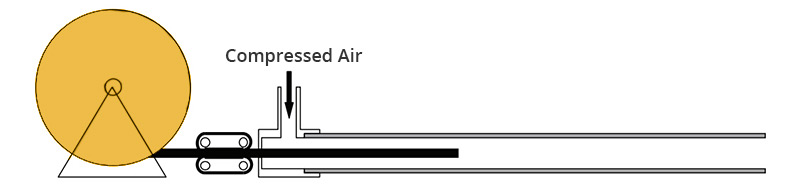

This method involves blowing or floating cables through the duct using compressed air or special lubricants. The cables are attached to a pulling device, and compressed air or lubricant is used to push or pull them through the duct. This method is often used for longer distances and larger diameter ducts.

Limitations: Special air blowing equipment are required for air blowing method. Air blowing of fiber cable into duct systems requires continuous run of inner-duct and pressure testing for integrity. Quality of inner-duct joints is critical to the success of air blowing techniques.

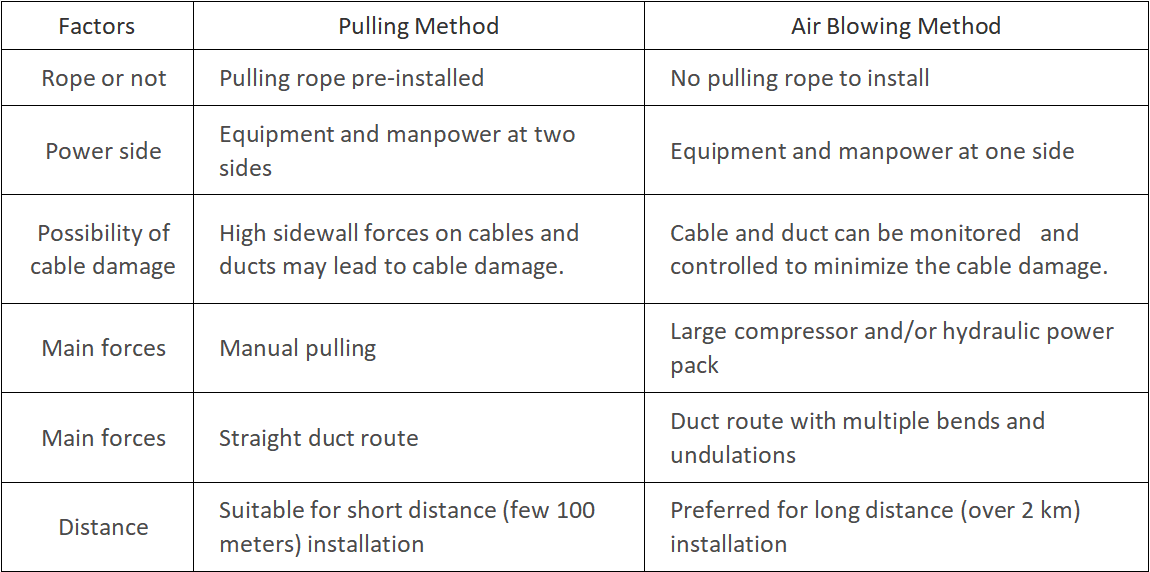

Site conditions, availability of machinery and resources are crucial factors for choosing cable installation method. The differences between pulling method and air blowing method for optical fiber cable installation are shown in the table below.